Quality Control

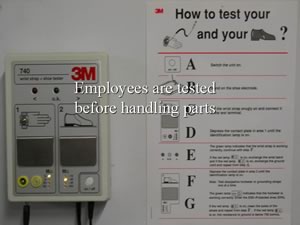

Parts are opened in an ESD/MSD compliant area for inspection of the actual items:

- MSD tab is checked for moisture intrusions, if necessary parts will be baked and resealed at an approved test house (certification of this process provided).

- Date code inconsistencies are checked.

- The markings on the part are checked for authenticity.

- Leads are inspected by hand held devices and by microscope if deemed necessary.

If any issues are identified Select then has the following options:

- Reject parts immediately and contact our vendor for an RMA.

- Send parts to be “de-lidded” (destructive physical analysis or DPA) for an inspection of the die and internal wiring.

- Send parts to Select test house to be tested and certified for solderability.

Member of Independent Distributors

of Electronics Association (IDEA)

- AS9120:2016

- ISO 9001:2015

- ANSI/ESD S20.20-2007